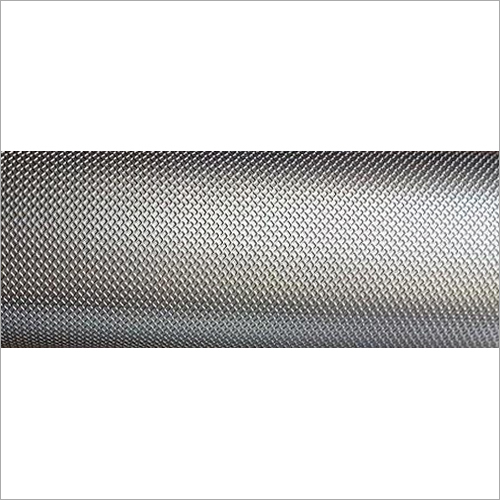

Embossing Roller

Embossing Roller Specification

- Capacity

- High Output & Continuous Operation

- Diameter

- Custom Sized / As per requirement

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Customized

- Dimensions

- Customized

- Product Type

- Embossing Roller

- Technique

- Precision Embossing

- Standard

- Industrial Grade

- Belt Width

- Customizable

- Feature

- Corrosion Resistant, High Durability

- Weight

- As per Dimensions and Design

- Packing Type

- Wooden Case / Export Standard Packaging

- Surface Finish

- Mirror Polished / Chrome Plated

- Core Type

- Solid / Hollow

- Hardness

- 48-55 HRC

- Application

- Textile, Paper, Leather, Film Embossing

- Mounting Type

- Flange / Shaft Mounted

- Roller Length

- As per client specification

- Tolerance

- ±0.05 mm

- Pattern Type

- Varied (On Request)

- Temperature Resistance

- Up to 250°C

Embossing Roller Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Embossing Roller

Embossing Roller is a quality-assured and long-lasting product that is designed and developed in our ultra-advanced production site with the help of pioneering in-house tools and techniques. This roller is typically used for delivering embossed patterns onto the substrates. It has got unmatched resilience, robust design, and ruggedness, therefore, the offered roller does not degrade in quality or become inferior in the long run. Embossing Roller comes in varied sizes and types as per the requirements of our customers.

Superior Surface Finish and Durability

Our rollers undergo advanced mirror polishing and chrome plating, providing a flawless finish and enhanced corrosion resistance. Hardness levels of 48-55 HRC ensure consistent performance even under demanding operational conditions. The high-grade stainless steel construction further contributes to prolonged service life and durability.

Customizable for Diverse Industrial Needs

We tailor every aspect of our embossing rollersincluding size, pattern, diameter, roller length, belt width, and core typeto precisely suit your requirements. Whether you need solid or hollow cores, flange or shaft mounting, our engineering team is equipped to deliver flexible solutions for any embossing application.

Precision Engineering for Reliable Performance

With tight tolerances (0.05 mm) and a continuous operating capacity, our rollers excel in delivering intricate and consistent patterns. Heat resistance up to 250C makes them suitable for various material processing. Each roller is manufactured to industrial grade standards using precision embossing techniques for consistent results.

FAQs of Embossing Roller:

Q: How can I customize an embossing roller for my specific industrial application?

A: You can provide your desired specifications such as pattern type, roller length, diameter, belt width, core type, mounting type, and required dimensions. Our manufacturing team will tailor the embossing roller precisely to your requirements, ensuring compatibility with your production setup.Q: What materials are used in these embossing rollers and what benefits do they offer?

A: We use high-grade stainless steel for our rollers, offering excellent corrosion resistance, high durability, and stability during continuous operation. The mirror-polished and chrome-plated surface ensures an optimal finish for embossing applications.Q: When should I choose a solid core versus a hollow core for the embossing roller?

A: Solid core rollers are ideal for applications demanding maximum strength and stability, while hollow core rollers are suitable for installations requiring reduced weight or specific operational parameters. Selection depends on your machinery and processing needs.Q: Where can these embossing rollers be used and what industries do they serve?

A: Our rollers are widely used in textile, paper, leather, and film embossing industries across India and internationally. Their industrial-grade design and customizable features make them suitable for a vast array of material processing sectors.Q: What is the process for pattern customization on these rollers?

A: You can request varied patterns tailored to your specific requirements. Patterns are precision-engraved onto the roller surface using advanced techniques, ensuring clarity and consistency in every embossed product.Q: How do these embossing rollers enhance operational efficiency?

A: With high output capacity, continuous operation, and precise tolerances, these rollers maintain consistent embossing quality, reduce downtime, and optimize throughput in industrial workflows.Q: What type of packaging is used to ensure safe delivery of the rollers?

A: We pack embossing rollers in robust wooden cases or export standard packaging to safeguard them from damage during transport and storage, ensuring they reach your facility in perfect condition.

Price 20000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Embossing Roller Category

Paper Embossing Roller

Price 20000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Size : Customized

Usage : Industrial

Feature : Corrosion Resistant, High Durability

Glass Embossing Roller (2)

Price 40000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Size : Standard

Usage : Glass industry

Feature : High Quality

Embossing Roller For Rexine

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Size : Standard

Usage : Industrial

Feature : High Quality

Aluminum Foil Embossing Roller (2)

Minimum Order Quantity : 1 Piece

Material : Aluminium

Size : Standard

Usage : Industrial

Feature : High Quality