Embossing Roller For Rexine

Embossing Roller For Rexine Specification

- Capacity

- Heavy Duty

- Diameter

- According to requirements

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Customized

- Dimensions

- Customized as per client

- Product Type

- Embossing Roller For Rexine

- Technique

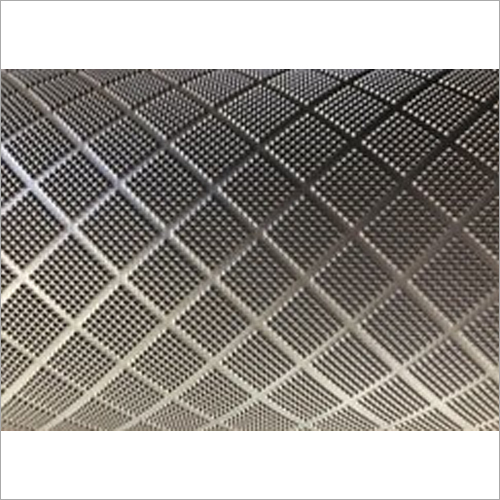

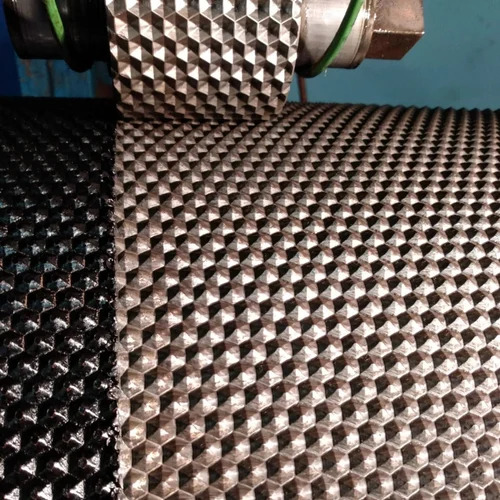

- Advanced Surface Engraving

- Standard

- Industrial

- Belt Width

- Customized

- Feature

- High Precision Embossing

- Production Rate

- High Output

- Hardness

- Optimized for Long Life

- Mounting

- Compatible with Standard Machinery

- Application

- Rexine/Textile Embossing Lines

- Maintenance

- Low

- Surface Finish

- Mirror Polished

- Corrosion Resistance

- Yes

- Pattern Type

- Multiple Designs Available

- Temperature Resistance

- High

Embossing Roller For Rexine Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- INDIA

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 40 Pieces Per Month

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard Packing & As Per Requirement

- Main Export Market(s)

- Asia, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO

About Embossing Roller For Rexine

We are instrumental in supplying Embossing Roller For Rexine that is used to create patterns on a substrate. The roller has got unmatched quality, resilience, and ruggedness. Owing to its high performance and longevity, it is preferred by our customers. Embossing Roller For Rexine does not degrade in quality or become inferior in the long run. It is mainly designed to deliver precise patterns onto a variety of nonwoven materials. The offered Embossing Roller For Rexine can endure chemical attacks, moisture, wear, and other degrading factors.

High Precision and Customization

Engineered for optimal surface finish, every embossing roller incorporates advanced surface engraving techniques and customizable dimensions. Multiple design patterns and belt widths can be tailored to exact specifications, enabling seamless integration into diverse industrial applications.

Robust Performance and Durability

Built for heavy-duty use, our rollers are made from corrosion-resistant stainless steel and optimized for long life. Their high temperature resistance and low maintenance requirements make them a dependable choice for continuous and high-output rexine/textile production lines.

Reliable Supply Across India

As a leading manufacturer, distributor, and supplier in India, we ensure accessible support and swift delivery of embossing rollers to meet the demands of textile and rexine industries. Each product adheres to stringent industrial standards for quality and consistency.

FAQs of Embossing Roller For Rexine:

Q: How is the embossing roller installed on standard machinery?

A: Our embossing rollers are designed to be compatible with standard industrial machinery, ensuring straightforward mounting. Customized dimensions and belt widths allow easy adaptation to existing setups without extensive modification.Q: What materials and surface finishes are available for the rollers?

A: The rollers are primarily crafted from high-grade stainless steel and finished with a mirror polish, delivering an immaculate surface. Various pattern designs can be incorporated to suit specific requirements for rexine and textile embossing.Q: When should the embossing roller be replaced or serviced?

A: Thanks to its optimized hardness and advanced surface technology, the roller requires minimal maintenance. Replacement or servicing is only necessary after extended, high-output cycles or if pattern degradation impacts embossing precision.Q: Where can the embossing rollers be used within industrial settings?

A: These rollers are intended for rexine and textile embossing lines in industrial environments. Their heavy-duty build and high temperature resistance make them ideal for continuous operation in large-scale production facilities.Q: What is the process used for engraving patterns on the rollers?

A: Advanced surface engraving techniques are employed to apply multiple pattern designs onto the roller. This process ensures high precision and uniformity, delivering consistent embossing quality across all produced materials.Q: How do these rollers benefit rexine and textile manufacturers?

A: Manufacturers benefit from high output rates, improved surface finishes, and reduced downtime due to the rollers durability and low maintenance needs. The ability to customize patterns and dimensions enhances production versatility and market responsiveness.

Price 20000.00 INR/ Piece

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 40 Pieces Per Month

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia, Middle East, Africa

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Embossing Roller Category

Tissue Paper Embossing Roller

Price 20000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Feature : Heat Resistant, Corrosion Resistant, Precision Finish

Size : Customized

Usage : Industrial

Cloth Embossing Roller

Price 30000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Feature : High Quality

Size : Standard

Usage : Textiles industry

Mask Embossing roller

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Feature : High Quality

Size : Standard

Usage : Industrial

Glass Embossing Roller

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Feature : High Quality

Size : Standard

Usage : Glass industry