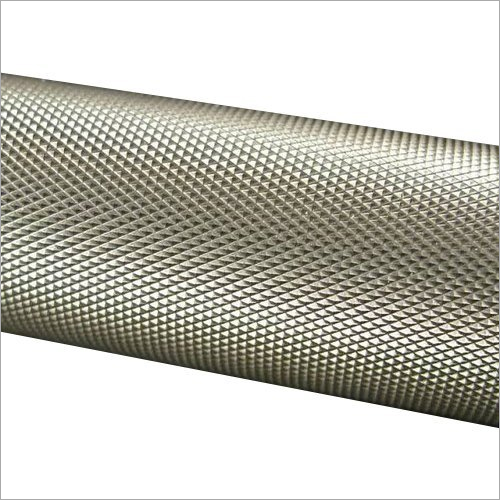

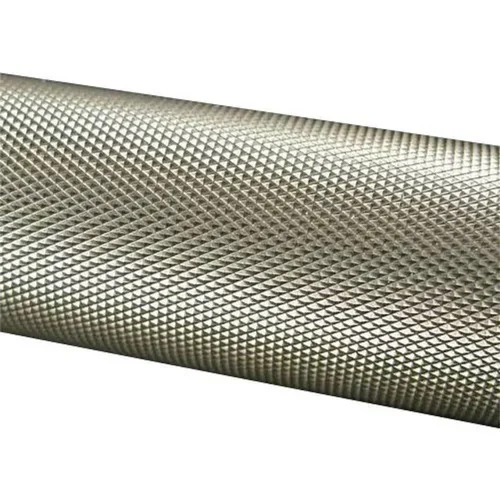

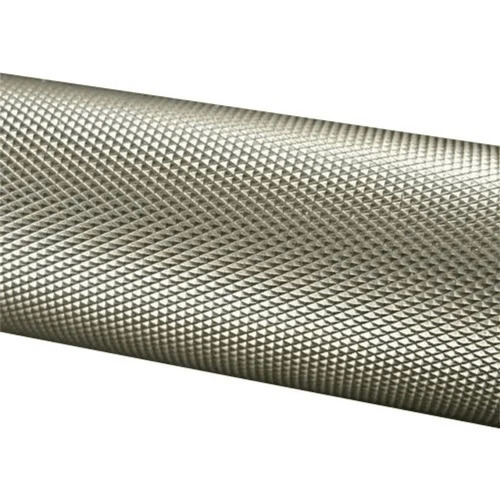

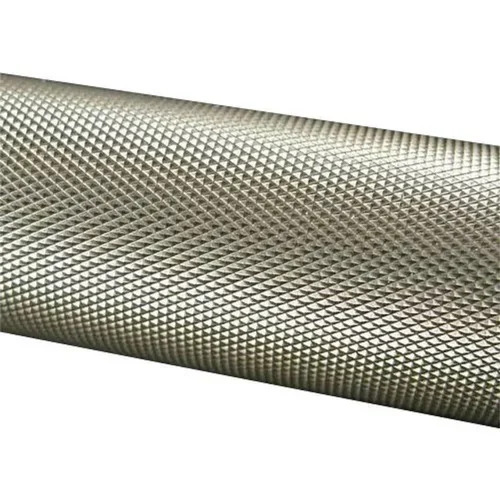

Industrial Knurling Roller

Industrial Knurling Roller Specification

- Diameter

- As per Requirement

- Usage

- Industrial

- Size

- Customized

- Product Type

- Industrial Knurling Roller

- Capacity

- Heavy Duty Industrial Application

- Material

- Stainless Steel

- Dimensions

- Customized

- Technique

- Knurling

- Standard

- Industrial Grade

- Belt Width

- Customized

- Feature

- Corrosion Resistant, High Precision

Industrial Knurling Roller Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Industrial Knurling Roller

Precision Engineering for Industrial Applications

With its high hardness and advanced knurling technique, this roller provides unmatched durability and performance in environments demanding close tolerance and high precision. The combination of customizable dimensions and industrial-grade standards ensures a perfect fit for diverse machinery and process lines.

Versatile Patterns and Superior Surface Finish

The polished, metallic silver surface not only enhances aesthetics but also optimizes wear resistance. Users can select from cross, straight, or diamond knurling patterns to achieve desired friction or grip, supporting functions from material handling to precise sheet forming.

Mounting and Maintenance Advantages

Shaft-mounted and offered with flanged or plain ends, installation is straightforward and secure. The use of premium stainless steel enables exceptional corrosion resistance, while low-maintenance requirements minimize downtime, maximizing operational efficiency for continuous industrial use.

FAQs of Industrial Knurling Roller:

Q: How is the industrial knurling roller installed in machinery?

A: The roller is designed for shaft mounting and is available with either plain or flanged end designs, allowing easy and secure installation into various industrial equipment according to belt width and diameter requirements.Q: What knurling patterns can be selected for this roller?

A: Customers can choose from cross, straight, or diamond knurling patterns, depending on their specific application needs in printing, packaging, textile, or sheet metal forming processes.Q: When should I use a high hardness knurling roller with close tolerance?

A: High hardness with close tolerance is best utilized when your process demands precise material handling and enhanced grip, such as in heavy-duty industrial applications requiring consistent product quality and durability.Q: Where is this roller typically distributed and supplied?

A: The industrial knurling roller is available through recognized distributors, manufacturers, and suppliers across India, ensuring wide accessibility for diverse industrial sectors.Q: What benefits does the polished surface finish provide?

A: A polished surface finish facilitates smoother operation, reduces wear and tear, and resists corrosion, making it suitable for applications in demanding environments.Q: How does the customization of size and dimensions work?

A: Customers can specify required dimensions, diameter, and belt width to match their machinery and operational needs, enabling precise integration into existing systems.Q: What is the maintenance process for this roller?

A: Owing to its robust stainless steel construction and high temperature resistance, the roller requires minimal maintenanceregular cleaning and inspection suffice to retain optimal performance.

Price 25000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Knurling Roller Category

MS Knurling Roller

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : High Precision, Corrosion Resistant

Product Type : MS Knurling Roller

Material : Stainless Steel

Size : Customized

Ms Knurling Roller

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : High Quality

Product Type : Ms Knurling Roller

Material : Stainless Steel

Size : Standard

Steel Knurling Roller

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : High Quality

Product Type : Steel Knurling Roller

Material : Mild Steel

Size : Standard

Stainless Steel Knurling Roller

Minimum Order Quantity : 1 Piece

Feature : High Quality

Product Type : Stainless Steel Knurling Roller

Material : Stainless Steel

Size : Standard