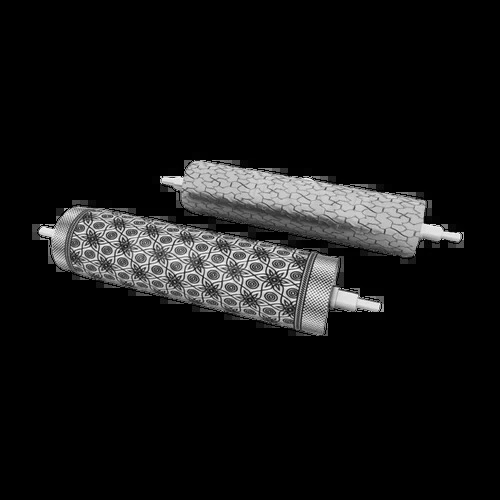

Joint Less Anilox Roller

Joint Less Anilox Roller Specification

- Capacity

- High Ink Transfer

- Product Type

- Joint Less Anilox Roller

- Diameter

- As per Requirement

- Size

- Customized

- Usage

- Industrial

- Material

- Stainless Steel

- Dimensions

- Customized

- Technique

- Laser Engraved

- Standard

- Industrial

- Belt Width

- Customized

- Feature

- Joint Less, High Precision

Joint Less Anilox Roller Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Joint Less Anilox Roller

Joint Less Anilox Roller is widely acclaimed among our customers owing to its high build quality, unmatched strength, and resilience. This roller is made to perfection with the help of advanced tools and techniques. It is mainly used for delivering different sorts of patterns and designs onto the substrate. We have different surface finish rollers to support all sorts of embossing. Owing to its high build quality, unmatched strength, and longevity, we are seeing a huge demand for the Joint Less Anilox Roller in the marketplace.

Superior Ink Transfer and Uniformity

Engineered with precision, the laser-engraved cell volume on the Joint Less Anilox Roller ensures uniform and consistent ink distribution, resulting in vivid, high-quality print results. The rollers smooth chromium-plated surface supports maximum line screens up to 1200 LPI, making it suitable for demanding flexographic and gravure printing applications.

Long-Lasting Performance with Easy Maintenance

With a hardness of over 1000 Vickers and excellent corrosion resistance, this anilox roller offers exceptional durability and a long service life. Maintenance is straightforward due to the easy-to-clean surface, minimizing downtime and maximizing productivity for industrial users.

FAQs of Joint Less Anilox Roller:

Q: How is the Joint Less Anilox Roller installed in printing machines?

A: The roller is designed for easy integration using either mechanical or pneumatic mounting systems, making it compatible with a wide range of flexographic and gravure printing presses.Q: What benefits does the jointless design offer compared to traditional anilox rollers?

A: The jointless construction eliminates seams that can cause inconsistencies, resulting in smoother operation, better print quality, and reduced risk of wear or failure during high-volume production.Q: When should I consider replacing my existing anilox roller with this high-precision model?

A: If your current roller shows signs of wear, uneven ink distribution, or reduced print quality, upgrading to our jointless, laser-engraved anilox roller will enhance your process reliability and print results.Q: Where can I use this roller, and what applications is it best suited for?

A: This roller is ideal for industrial flexographic and gravure printing operations, including packaging, labels, and other high-precision printing tasks requiring consistent ink transfer and superior surface finish.Q: What is the cleaning process for maintaining the rollers performance?

A: Regular, gentle cleaning with recommended non-abrasive solutions will preserve the smooth chromium-plated surface and maintain optimal cell volume for uniform ink transfer, extending the rollers service life.Q: How does the optimized cell volume help in printing applications?

A: Optimized cell volume ensures uniform and controlled ink distribution, minimizing waste and ensuring sharp, high-definition prints, even at maximum line screens up to 1200 LPI.

Price 25000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Anilox Roller Category

Industrial Anilox Roller

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Customized

Usage : Industrial

Material : Stainless Steel

Product Type : Industrial Anilox Roller

Anilox Coating Roller

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Customized

Usage : Industrial

Material : Stainless Steel

Product Type : Anilox Coating Roller

Anilox Coating Roller

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Usage : Printing Industry

Material : Stainless Steel

Product Type : Anilox Coating Roller

Fabric Embossing Roller

Minimum Order Quantity : 1 Piece

Size : Standard

Usage : Industrial

Material : Stainless Steel

Product Type : Fabric Embossing Roller