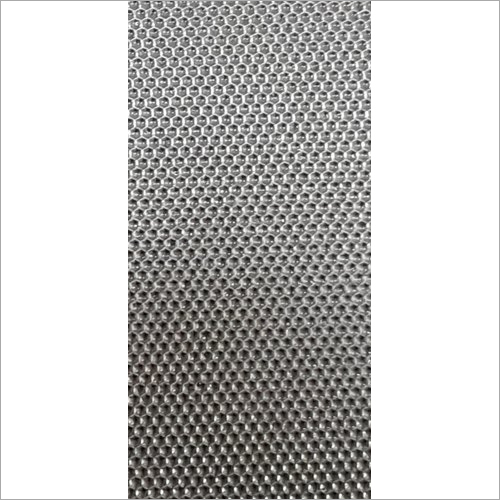

Mother Roll Of Nickel Screen

Mother Roll Of Nickel Screen Specification

- Surface Finish

- Smooth

- Usage & Applications

- Textile Printing, Rotary Screen Printing Machines

- Size

- Custom or standard as per specification

- Shape

- Cylindrical

- Capacity

- Varies by dimension and application

- Noise Level

- Silent Operation

- Lubricating System

- None Required

- Features

- High precision mesh structure, corrosion resistant, long service life, easy installation

- Diameter

- Standard diameters available (e.g., 640 mm, 914 mm)

- Product Type

- Other

- Material

- Stainless Steel

- Technology

- Electroforming

- Power Source

- Manual

- Surface Treatment

- Painted

- Dimension (L*W*H)

- Customizable

- Weight

- Approximately 50-200 kg per roll

- Color

- Silver/Grey

- Tensile Strength

- High

- Storage Recommendations

- Store in dry, dust-free environment

- Packaging Type

- Protective wrapping with waterproof materials

- Mesh Count

- 40-165 mesh options available

- Perforation Type

- Customizable as per textile requirement

- Max Operating Temperature

- Up to 200°C

- Lead Time

- As per order size

- Compatibility

- Suitable for all major rotary printing systems

Mother Roll Of Nickel Screen Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Mother Roll Of Nickel Screen

Mother Roll Of Nickel Screen is unmatched in terms of design and performance. This is used typically to deliver patterns on different kinds of substrates. The product is made up of the first-rate raw material with the help of pioneering in-house tools and techniques. Owing to its longevity, resilience, and reliable performance, we are seeing a huge demand for nickel screen in the marketplace. Mother Roll Of Nickel Screen comes in varied sizes and types as per the requirements of our customers.

Advanced Nickel Screen for Textile Printing

Our nickel screens utilize electroforming technology for accurate mesh structure and superior durability. With customizable mesh and perforation options, these screens meet the precise demands of rotary textile printing. Their smooth surface finish and corrosion-resistant properties ensure efficient production and optimal print quality in every use.

Custom Sizing and Reliable Packing

We provide mother rolls in both standard and custom dimensions, with diameters like 640 mm and 914 mm available. Each screen is securely wrapped in waterproof protective materials, guaranteeing safe delivery. Fast lead times and detailed specifications allow seamless integration into existing rotary screen printing machines.

Enhanced Durability and Silent Operation

Thanks to high tensile strength and advanced surface treatments, the screens offer long service life and maintain silent operation. The structure remains intact even at operating temperatures up to 200C, making them a robust choice for high-volume textile production environments.

FAQs of Mother Roll Of Nickel Screen:

Q: What mesh count and perforation types are available for the Mother Roll of Nickel Screen?

A: Mesh counts range from 40 to 165, and perforation types can be fully customized as per textile printing requirements, providing versatility for various printing patterns and fabric types.Q: How does the product benefit textile printing operations?

A: The precision mesh structure ensures consistent ink flow and high print quality, while corrosion resistance and smooth surfaces extend operational life, reducing downtime and maintenance costs.Q: When can I expect delivery after placing an order?

A: Lead time varies according to order size and customization needs. Delivery schedules are communicated upfront, ensuring alignment with your production timelines.Q: Where can these screens be used?

A: They are compatible with all major rotary screen printing systems, making them ideal for textile printing facilities, rotary printing machine manufacturers, and suppliers across India.Q: What is the process for installation and maintenance?

A: Installation is straightforward due to the cylindrical shape and standard fit for rotary machines. No lubrication is required, and silent operation minimizes wear, making maintenance simple and infrequent.Q: How should the nickel screen rolls be stored to maintain quality?

A: Store the rolls in a dry, dust-free environment to preserve their smooth finish and prevent corrosion. The protective waterproof packaging also aids in maintaining optimal condition during transit and before use.Q: What advantages does the electroforming technology offer?

A: Electroforming delivers high precision mesh and robust tensile strength, resulting in improved durability, outstanding performance during printing, and suitability for demanding textile applications.

Price 25000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email