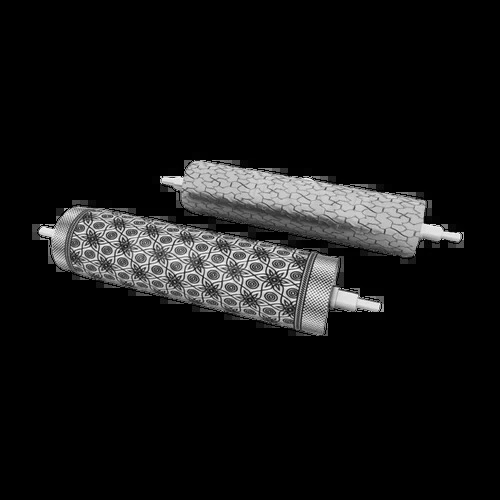

Anilox Coating Roller

Anilox Coating Roller Specification

- Diameter

- Up to customer requirement

- Capacity

- High volume ink/varnish transfer

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Customized

- Product Type

- Anilox Coating Roller

- Dimensions

- Customized as per requirement

- Technique

- Laser engraved ceramic coating

- Standard

- As per industry norms

- Belt Width

- Customized

- Feature

- Wear-resistant, High Precision

- Application

- Flexographic, Gravure, and Offset Printing

- Hardness

- Up to 1200 Vickers

- Engraving Method

- Laser / Mechanical

- Cell Volume

- 1.0 - 70 BCM (Billion Cubic Microns)

- Maximum Weight

- Up to 800 kg

- Surface Finish

- Smooth with ceramic or chrome coating

- Corrosion Resistance

- Excellent

- Cleaning Compatibility

- Ultrasonic and chemical cleaning safe

- Mounting Type

- Flange or shaft mounted

- Roller Core Material

- Steel/Aluminum (on request)

- Maximum Length

- Up to 4000 mm

- Tolerance

- Fine tolerance up to ±0.01 mm

Anilox Coating Roller Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Anilox Coating Roller

Experience optimum performance with the Anilox Coating Roller, designed for competitive pricing and unmatched value. Crafted with a rare blend of dazzling precision and wondrous surface finishing, this roller features a smooth ceramic or chrome coating and a hardness reaching up to 1200 Vickers. Its high cell volume (1.070 BCM) ensures efficient ink or varnish transfer for flexographic, gravure, and offset printing. With corrosion resistance, fine tolerance (up to 0.01 mm), and compatibility for ultrasonic and chemical cleaning, this roller is engineered for durability and distinguished wear-resistance. Custom sizes, mounting styles, and belt widths available.

Exceptional Features for Industrial Excellence

The Anilox Coating Roller stands out with its high precision, wear-resistant ceramic or chrome coating, smooth surface finish, and rare capability of cell volumes up to 70 BCM. Ideal for flexographic, gravure, and offset printing applications, it delivers fine tolerance and corrosion resistance. Extra features include high-volume ink/varnish transfer, customizable dimensions, and compatibility with ultrasonic/chemical cleaning for effortless upkeep. This wondrous product meets rigorous industry standards and is tailored for heavy-duty industrial usage.

Secure Packaging and Rapid Dispatch Nationwide

Each Anilox Coating Roller is securely packaged using robust materials to safeguard against damage during transit. Available across Indias main domestic markets, we facilitate quick dispatch and ensure orders reach your facility efficiently. With our competitive sale price and reliable delivery timelines, the product is dispatched promptly after order confirmation, so your operations remain uninterrupted. Trust our process for quality assurance from order to delivery at optimum speed and value.

Exceptional Features for Industrial Excellence

The Anilox Coating Roller stands out with its high precision, wear-resistant ceramic or chrome coating, smooth surface finish, and rare capability of cell volumes up to 70 BCM. Ideal for flexographic, gravure, and offset printing applications, it delivers fine tolerance and corrosion resistance. Extra features include high-volume ink/varnish transfer, customizable dimensions, and compatibility with ultrasonic/chemical cleaning for effortless upkeep. This wondrous product meets rigorous industry standards and is tailored for heavy-duty industrial usage.

Secure Packaging and Rapid Dispatch Nationwide

Each Anilox Coating Roller is securely packaged using robust materials to safeguard against damage during transit. Available across Indias main domestic markets, we facilitate quick dispatch and ensure orders reach your facility efficiently. With our competitive sale price and reliable delivery timelines, the product is dispatched promptly after order confirmation, so your operations remain uninterrupted. Trust our process for quality assurance from order to delivery at optimum speed and value.

FAQs of Anilox Coating Roller:

Q: How is the Anilox Coating Roller beneficial for printing applications?

A: The Anilox Coating Roller delivers precise and consistent ink or varnish transfer, improving print quality and operational efficiency for flexographic, gravure, and offset printing.Q: What materials and coatings are available for the roller?

A: You can choose between a ceramic or chrome coating over a steel core, and aluminum roller cores are also available on request to suit specific requirements.Q: Where can I use the Anilox Coating Roller?

A: It is suitable for industrial usage in printing operations, including flexographic, gravure, and offset printing processes across various manufacturing sectors.Q: When will my order for the Anilox Coating Roller be delivered?

A: Your order will be quickly dispatched and delivered nationwide according to our reliable timelines, ensuring minimal downtime for your operations.Q: What process is used for engraving the roller cells?

A: The roller features laser or mechanical engraving techniques, ensuring the cell structure is precise, consistent, and optimized for high-volume ink transfer.Q: How is the roller cleaned and maintained?

A: Anilox Coating Rollers are compatible with ultrasonic and chemical cleaning methods, providing efficient maintenance and prolonging the products lifespan.

Price 25000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Anilox Roller Category

Industrial Anilox Roller

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Customized

Material : Stainless Steel

Usage : Industrial

Product Type : Industrial Anilox Roller

Joint Less Anilox Roller

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Customized

Material : Stainless Steel

Usage : Industrial

Product Type : Joint Less Anilox Roller

Anilox Coating Roller

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : Standard

Material : Stainless Steel

Usage : Printing Industry

Product Type : Anilox Coating Roller

Fabric Embossing Roller

Minimum Order Quantity : 1 Piece

Size : Standard

Material : Stainless Steel

Usage : Industrial

Product Type : Fabric Embossing Roller