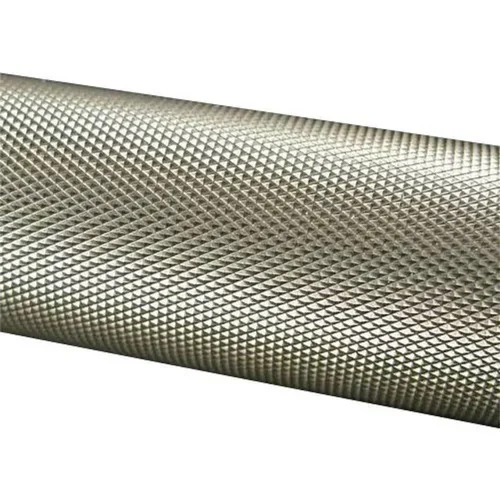

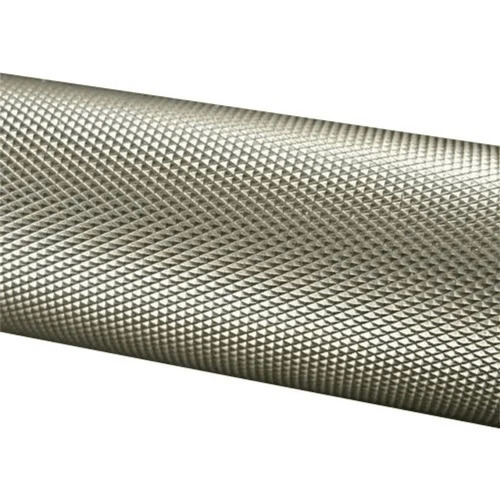

Knurling Gumming Roller

Knurling Gumming Roller Specification

- Usage

- Industrial

- Diameter

- 110 mm

- Capacity

- High Load Bearing

- Size

- Customized

- Product Type

- Knurling Gumming Roller

- Material

- Stainless Steel

- Dimensions

- Customized as per requirement

- Technique

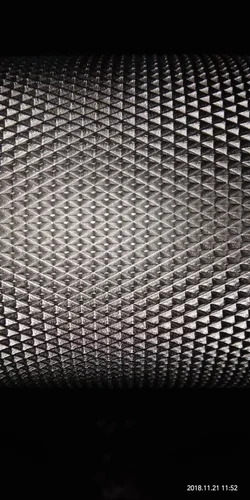

- Knurling and Precision Machining

- Standard

- Industrial Grade

- Belt Width

- Up to 1500 mm

- Feature

- High Precision Knurling, Enhanced Adhesion

Knurling Gumming Roller Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Knurling Gumming Roller

Knurling Gumming Roller is unmatched in terms of design and performance. This is typically used for delivering precise patterns onto the substrate. The roller is made out of the first-rate raw material that is extremely resilient, long-lasting, and rugged material. therefore, this product does not degrade in quality or become inferior in the long run. Knurling Gumming Roller comes in different sizes and styles. Our customers can approach us to get this roller delivered to their doorstep within the committed time frame.

Engineered for Industrial Performance

Knurling Gumming Rollers are meticulously manufactured to endure demanding industrial environments. Their solid stainless steel core and high-precision knurling process ensure consistent surface grip and superior durability, even under high-temperature conditions and heavy loads. These qualities make them indispensable across various manufacturing sectors.

Customizable to Suit Your Specific Needs

Whether you require specific dimensions, belt widths up to 1500 mm, or flanged mounting options, each Knurling Gumming Roller can be tailored to meet your application requirements. This flexibility ensures seamless integration into your production workflow and optimal performance, regardless of your unique industrial challenges.

Low Maintenance, Extended Service Life

With a corrosion-resistant finish and robust construction, these rollers are designed for minimal upkeep. Their high hardness (HRC 50-60) and enhanced tensile strength guarantee a longer lifespan, reducing downtime and total cost of ownership for plant operators and manufacturers.

FAQs of Knurling Gumming Roller:

Q: How is the knurling gumming roller manufactured to achieve high precision and strength?

A: Each roller is engineered using advanced knurling and precision machining processes on solid stainless steel cores. This ensures a smooth, corrosion-resistant surface and optimal knurling pattern, resulting in high tensile strength and extended durability for industrial applications.Q: What are the benefits of using a roller with a hardness of HRC 50-60 and corrosion-resistant finish?

A: The specified hardness range provides excellent wear resistance and load-bearing capability, while the corrosion-resistant surface ensures a long service life and stable performance even in harsh industrial environments.Q: When should I consider customizing the roller size or belt width for my operation?

A: Customization is recommended when your application involves unique machinery dimensions, belt widths up to 1500 mm, or specific mounting requirements, ensuring optimal integration and efficiency in your production process.Q: Where can these rollers be installed for maximum efficiency?

A: Knurling Gumming Rollers are suitable for various industrial settings, including manufacturing lines, processing equipment, and conveyor systems across factories in India. Their flanged or standard mounting options facilitate versatile installation.Q: What is the typical process for maintaining these rollers?

A: Routine visual inspections and periodic cleaning are generally sufficient due to the rollers low maintenance design. The corrosion-resistant stainless steel and robust construction minimize the need for frequent servicing or replacements.Q: How does precision knurling enhance the rollers performance in industrial applications?

A: Precision knurling creates uniform surface patterns that improve material adhesion and grip, resulting in better control, reduced slippage, and increased productivity during industrial processing.

Price 25000 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Knurling Roller Category

Industrial Knurling Roller

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Feature : Corrosion Resistant, High Precision

Material : Stainless Steel

Size : Customized

Ms Knurling Roller

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Feature : High Quality

Material : Stainless Steel

Size : Standard

Steel Knurling Roller

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Feature : High Quality

Material : Mild Steel

Size : Standard

Diamond Knurling Roller

Minimum Order Quantity : 1 Piece

Usage : Industrial

Feature : High Quality

Material : Mild Steel

Size : Standard