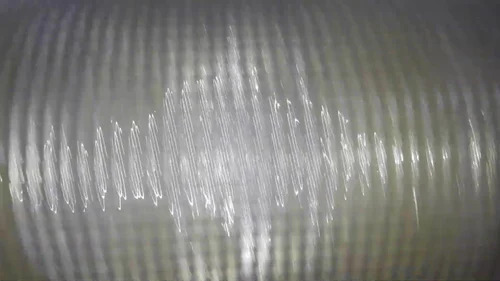

Industrial Embossing Roller

Industrial Embossing Roller Specification

- Capacity

- High Throughput

- Diameter

- Customizable

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Customized

- Dimensions

- Based on Requirement

- Product Type

- Industrial Embossing Roller

- Technique

- Advanced Engraving

- Standard

- Industrial

- Belt Width

- Customized

- Feature

- Precision Embossing

- Corrosion Resistance

- Superior

- Core Material

- Steel Alloy

- Mounting Type

- Shaft Mounted

- Surface Finish

- Mirror Polished

- Hardness

- 58-62 HRC

- Roller Length

- Up to 2500 mm

- Application

- Textile, Leather, Paper, Plastic, Nonwoven Industries

- Temperature Resistance

- Up to 300°C

- Embossing Depth

- 0.02 mm to 3 mm

- Tolerance

- ±0.03 mm

- Pattern Type

- Customizable Embossing Patterns

Industrial Embossing Roller Trade Information

- Minimum Order Quantity

- 10 Pieces

- Payment Terms

- Cash Advance (CA)

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Industrial Embossing Roller

Customizable Embossing Solutions

Tailored to meet diverse industrial needs, these rollers can be manufactured in customized dimensions and belt widths, ensuring compatibility with specific production requirements. The advanced patterning technology delivers detailed, intricate embossing to elevate product aesthetics and texture, enhancing value for end-users across multiple industries.

Precision and Durability for High-Volume Production

With a mirror-polished finish, superior corrosion resistance, and hardness between 58-62 HRC, this embossing roller minimizes wear and ensures consistent performance in continuous operations. Its high temperature resistance and rigid tolerances guarantee reliable results even under challenging manufacturing conditions.

FAQs of Industrial Embossing Roller:

Q: How is the Industrial Embossing Roller installed in production lines?

A: The roller is designed for shaft mounting, allowing straightforward integration into various industrial embossing machines, suitable for applications including textiles, leather, paper, and plastics.Q: What embossing patterns are available with this roller?

A: This roller supports fully customizable embossing patterns, made possible by advanced engraving techniques, adapting to precise customer specifications and industry standards.Q: When should I opt for a mirror-polished embossing roller?

A: A mirror-polished finish is ideal when you require high-definition, smooth embossing surfaces for premium products, ensuring minimal defects and superior texture quality.Q: Where is this roller commonly used?

A: It is utilized in textile, leather, paper, plastic, and nonwoven industry manufacturing facilities where precision embossing is a critical factor for product differentiation and quality.Q: What is the process for ordering a custom-sized roller?

A: You can specify your required roller length (up to 2500 mm), diameter, embossing depth, and pattern type. The manufacturer/distributor in India will design and fabricate the roller as per your industrial needs.Q: How does the roller benefit industrial production?

A: Its high throughput capability, minimal tolerance, corrosion resistance, and precise pattern reproduction enhance production efficiency, reduce downtime, and improve the consistency of finished products.Q: Can the roller withstand high operating temperatures?

A: Yes, the roller is engineered for temperature resistance up to 300C, making it suitable for demanding processes that involve elevated thermal conditions.

Price 20000.00 INR/ Piece

- Minimum Order Quantity

- 10 Pieces

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Embossing Roller Category

Embossing Roller

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Embossing Roller

Material : Stainless Steel

Feature : Corrosion Resistant, High Durability

Size : Customized

Mask Embossing roller

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Mask Embossing roller

Material : Stainless Steel

Feature : High Quality

Size : Standard

Car Mat Emboss Roller

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Car Mat Emboss Roller

Material : Stainless Steel

Feature : High Quality

Size : Standard

Embossing Roller Tissue Paper

Minimum Order Quantity : 1 Piece

Usage : Industrial

Product Type : Embossing Roller Tissue Paper

Material : Stainless Steel

Feature : High Quality

Size : Standard