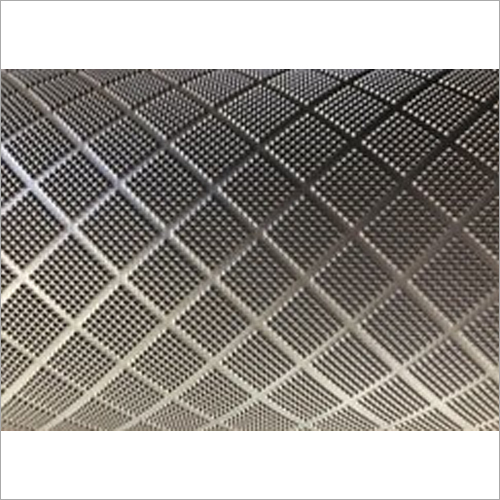

Mask Embossing roller

Mask Embossing roller Specification

- Capacity

- High-volume production

- Diameter

- As per customer requirement

- Product Type

- Mask Embossing roller

- Usage

- Industrial

- Size

- Customized

- Material

- Stainless Steel

- Dimensions

- Customized

- Technique

- Advanced CNC Machining

- Standard

- Industrial Grade

- Belt Width

- Customized

- Feature

- Precision Embossing Surface

Mask Embossing roller Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Mask Embossing roller

Superior Surface Finish for Precise Embossing

With its mirror-polished finish and precision grooves, this roller consistently delivers sharp, high-quality embossing patterns, crucial for industrial mask manufacturing. The customizable designs ensure each client receives a unique solution tailored to production needs.

Enhanced Durability and Corrosion Resistance

Built from stainless steel and designed for enhanced wear resistance, the roller withstands heavy industrial use and high temperatures. Excellent corrosion resistance ensures longevity, while maintenance requirements remain minimal, reducing downtime.

Customizable to Fit Any Production Line

Rolled out with advanced CNC machining, each roller is manufactured to fit the specific belt width, diameter, and dimensions required by the customer. This flexibility supports efficient integration into both manual and automated mask production environments.

FAQs of Mask Embossing roller:

Q: How is the embossing pattern customized on the Mask Embossing Roller?

A: The embossing pattern is tailored using advanced CNC machining, allowing manufacturers to specify designs that align with their mask production requirements.Q: What benefits does the mirror-polished surface finish provide?

A: A mirror-polished surface ensures precise and clear embossing impressions, minimizing defects and enhancing the quality of the finished masks.Q: When should the roller be maintained or inspected?

A: Due to its low maintenance needs, periodic visual inspections and cleaning after use are recommended to ensure optimal performance and longevity.Q: Where is the Mask Embossing Roller manufactured and supplied?

A: This roller is manufactured in India and is available through local distributors and suppliers for industrial mask production facilities.Q: What process is used to achieve enhanced wear resistance and corrosion resistance?

A: The roller is crafted from high-grade stainless steel using advanced CNC machining techniques and specialized surface treatments to boost its hardness and protect against corrosion.Q: How does the roller integrate with manual and automated operations?

A: Its design allows for easy mounting and compatibility with both manual and automated mask production lines, supporting diverse manufacturing setups.Q: What are the key advantages of customizing the roller dimensions and capacity?

A: Customizing diameter, belt width, and dimensions enables seamless adaptation to high-volume production environments and maximizes the efficiency of mask manufacturing operations.

Price 25000.00 INR/ Piece

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Embossing Roller Category

Tissue Paper Embossing Roller

Price 20000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Tissue Paper Embossing Roller

Usage : Industrial

Feature : Heat Resistant, Corrosion Resistant, Precision Finish

Size : Customized

KN 95 Mask Embossing Roller

Price 20000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : KN 95 Mask Embossing Roller

Usage : Industrial

Feature : High Precision, Durable

Size : Customized

Embossing Roller

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Embossing Roller

Usage : Industrial

Feature : Corrosion Resistant, High Durability

Size : Customized

Embossing Roller Tissue Paper

Minimum Order Quantity : 1 Piece

Product Type : Embossing Roller Tissue Paper

Usage : Industrial

Feature : High Quality

Size : Standard